SalmoAir®

Upwelling

for

Aquaculture

The success of marine aquaculture depends heavily on the favorable conditions of temperature, dissolved oxygen, pH and nutrient levels in water. The increase in surface water temperature may cause metabolic distress and asphyxia, resulting in stress and mortality of fish. Upwelling using air bubbles is being investigated as a method of controlling water temperature.

Executive Summary

Climate change and associated surface water temperature rise is major threat for the marine aquaculture industry worldwide. The success of marine aquaculture depends heavily on the favorable conditions of temperature, dissolved oxygen, pH and nutrient levels in water. During summer months, the increase in surface water temperature may cause metabolic distress and asphyxia, resulting in stress and mass mortality of fish. Upwelling using air bubbles is being investigated as a method of controlling water temperature. Upwelling is a process in which the deeper, colder water is lifted to surface providing thermal mixing and circulation of oxygen and nutrient rich water. In winter months, the deeper and relatively warmer water could also be upwelled to the surface to provide more favorable conditions for fish growth and keeping the water surface ice free. Although there is anecdotal evidence that the CanadianPond upwelling systems can provide adequate upwelling, their performances are not quantitatively assessed. Thus, the main objectives of this study are to conduct the validation and verification trials of the CanadianPond upwelling systems (i.e., SalmoAir® and OctoAir-60) for estimating their upwelling performance for use in marine aquaculture operations. This objective was achieved by conducting a field trial with the upwelling systems placed at 20 m below water surface for the system’s upwelling rate measurement, supplemented with numerical analysis. As a part of this study, the following tasks were completed:

• Test planning and concept development;

• Design, procurement and fabrication of test apparatus;

• Field trial and data analysis; and

The field trials were completed at The Launch facility in Holyrood Bay. C-CORE contracted a 35 ft vessel equipped with a crane that was used to deploy the upwelling systems over the side of the vessel and lower it to a depth of 20 m. A 6 m long instrumentation frame was used to lower and raise sensors to measure the vertical and horizontal water velocities and temperature as a function of depth.

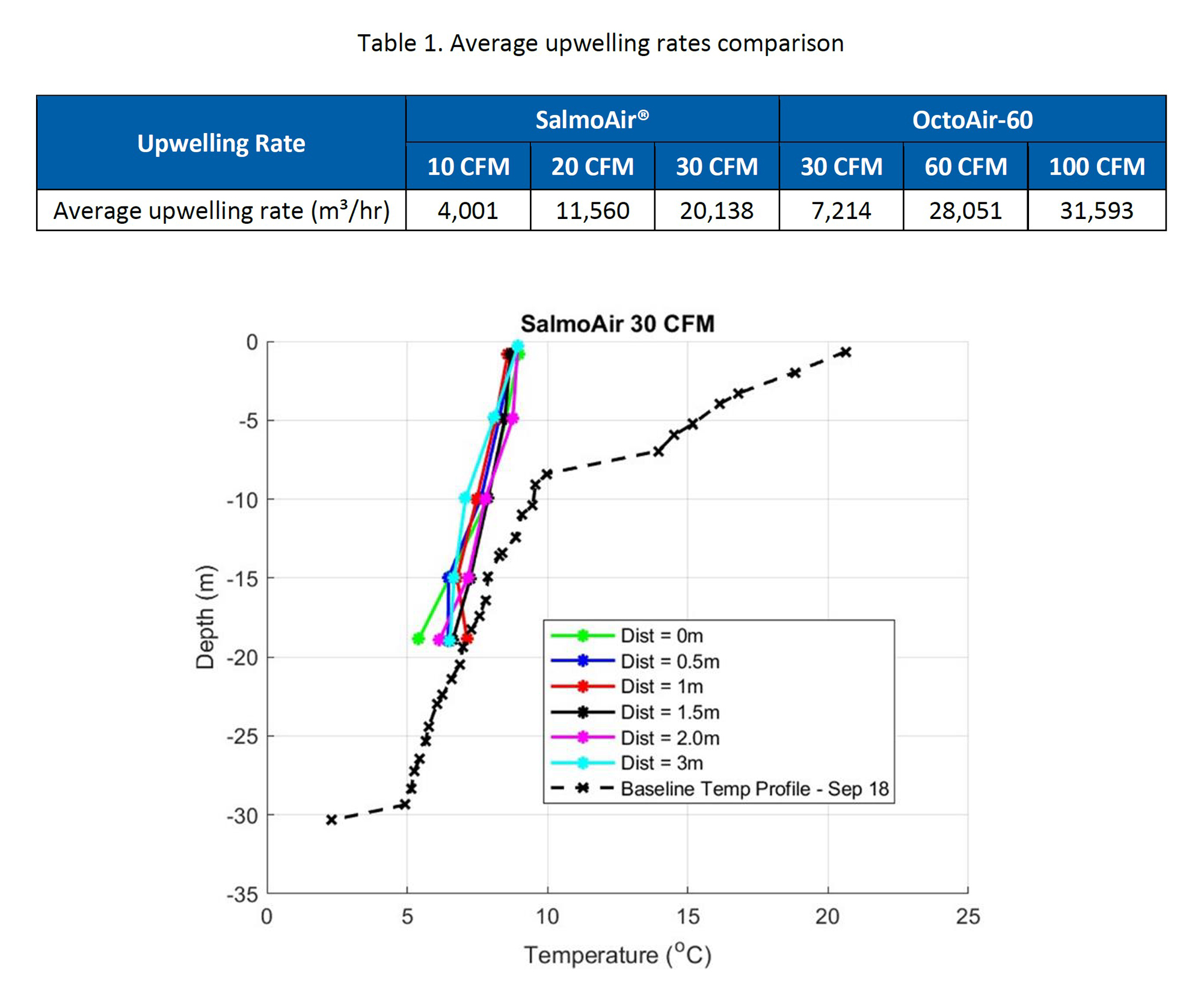

The background ocean current, Dissolved Oxygen (DO) level and water temperature were measured using an Acoustic Doppler Current Profiler (ADCP), an Oxyguard sensor and a temperature data logger, respectively. During testing, the instrumentation frame was lowered to depths such as 1, 5, 10, 15 and 19 m below surface for a duration of 5 minutes at each location to measure the generated vertical and horizontal velocities and temperature at these depths. Once a vertical drop is complete at the center of the plume, the sensor is moved horizontally at offsets of 0.5, 1, 1.5, 2, 3, 4 and 5 m away from center to map the vertical and horizontal velocities. Once the extent of plume and the vertical velocities are computed, the upwelling rates are estimated by combining the plume cross sectional area with vertical velocity. The estimated average upwelling rate for SalmoAir® and OctoAir-60 at the tested CFMs (Cubic Feet/Minutes) are summarized in the Table 1.

Through field trials, this study quantitatively estimated the performances of CanadianPond upwelling systems. Major conclusions from this study are presented below.

Upwelling Rates

• With 10 and 20 CFM airflow rates SalmoAir® produced 4,001 and 11,560 m3/hr upwelling rates, respectively, whereas the 30 CFM air flow rate produced 20,138 m3/hr upwelling rate. With 30 and 60 CFM air flow rates, the OctoAir-60 produced 7,214 and 28,051 m3/hr upwelling rates, respectively, whereas the 100 CFM air flow rate produced 31,593 m3/hr upwelling rate.

• The upwelling rates are found to increase with air flow rates passing through the diffuser, i.e., 30 CFM air flow rate produced the highest upwelling rate for SalmoAir® (20,138 m3/hr) and 100 CFM air flow rate produced the highest upwelling rate for OctoAir-60 (31,593 m3/hr).

• While comparing the performance of diffusers at the same air flow rate (e.g., at 30 CFM), the performance of SalmoAir® (20,138 m3/hr) was much better than that of the OctoAir-60 (7,214 m3/hr).

• When having significant compressor capacity (for e.g., 60 CFM), sending the air through two SalmoAir® (i.e., at 30 CFM) may be better than sending the entire air through a single OctoAir-60.

• Depending on the site conditions and cage size, this study provides a basis for selecting the number and type of diffusers required for adequate upwelling within the fish cage.

Vertical Velocity

• The cold water appears to be lifted to the surface by the following two processes:

o Kinetic energy - the exiting air bubbles cause an upward flow and momentum by imparting kinetic energy to the surrounding water particles; and

o Density change - the presence of air bubbles in water reduces the density of air-water mixture, causing the buoyancy force overtaking gravity leading to an upward motion.

• The vertical velocity increases as the air bubbles move towards the surface, before slowing near surface as the energy is translated to horizontal velocity, with the peak vertical velocity being observed at 5 m below surface.

• The highest vertical velocities were observed at the plume center. The vertical velocity decreased as the sensor moved horizontally away from the center.

• The highest value of average vertical velocity measured was 0.43 m/s for SalmoAir® with 30 CFM air, and 0.62 m/s for OctoAir-60 with 100 CFM air, both at 5 m below surface in the plume center. In order to find upper limit, a partial test was conducted with 180 CFM air flow with OctoAir-60, which resulted in a vertical velocity of 0.77 m/s at 5 m below surface in the plume center.

• When there is significant air flow through the diffuser (20 CFM or higher for SalmoAir® and 60 CFM or higher for OctoAir-60), the plume was observed to be strong vertically with low horizontal spread.

• At 30 CFM air flow rate, SalmoAir® produced better vertical velocities when compared to OctoAir-60.

Horizontal Velocity

• The measured horizontal velocity was insignificant (i.e., less than 0.1 m/s) for both SalmoAir® and OctoAir-60 at the plume center. At 3 m horizontal distance, the measured horizontal velocity was increased to 0.19 m/s at a depth of 1 m below surface. The horizontal velocity measured was insignificant at depths measured below 1 m.

Temperature

• Prior to starting tests, the ocean water was well stratified with 21°C at 1 m below, 16°C at 5 m below, 7°C at 20 m below (at diffuser location) and 2 - 3°C near seabed. During testing, the temperature 1 m below surface changed from 21°C initially to 7-9°C demonstrating the system performance (see Figure 1).

• The temperature is found to decrease at the plume center and it was found to increase as the sensor moved away horizontally from the center. This also indicates that the cold-water upwelling is happening due to the diffuser operation, resulting in reduced temperature within the plume.

Figure 1. Temperature – depth profile during SalmoAir® at 30 CFM testing vs. baseline temperature

Dissolved Oxygen

• The DO level was found to increase at the plume center and it was found to decrease as the sensor moved horizontally from the plume center to 3 m and 6 m away, respectively. This may be due to upwelling of deeper, colder water to surface within the plume, and mixing with surface warm water as the sensor moved away from the plume center. The cold water has higher DO levels.

• The minimal increase in the measured DO levels due to tested ranges of air flow rates (i.e., 10, 20 and 30 CFMs for SalmoAir® and 30, 60 and 100 CFMs for OctoAir-60) indicates that the increase in DO levels is predominantly due to the cold water (which has higher DO levels) upwelling. The depth of DO measurement was limited to 2 m below surface in this study, and therefore a further study including deep water DO measurement (up to 20 to 30 m) is recommended.

Ocean Current

The ADCP measured ocean current throughout the test period. The measured magnitude and direction of ocean current was different at near surface, mid-depth and near bottom. The ADCP data is only good before the test starts, and current direction and magnitude will change throughout the day due to changes in tides and weather conditions.

Recommendations for Future Work

Based on this study, the following recommendations are made for future work:

• The present study has shown that upwelling and temperature control is possible using the CanadianPond system, however integration with the cage, operational logistics, and the effects on the fish are unknown. Future studies could be conducted within a fish cage as a pilot project to study the effect of air bubbles on fish, temperature/thermocline, and DO and the resulting expected impact on fish health.

• The optimal location (i.e., inside vs. outside) and depth (i.e., within or below) for upwelling system installation with respect to the cage is not well studied in this project. Therefore, a future study including CFD modeling or field testing can help resolve these challenges.

• The depth of DO measurement was limited to 2 m below surface in this study. Therefore, a further study including deep water DO measurement is recommended to quantify the aeration potential.

• This study didn’t cover the energy requirements for upwelling projects, therefore, a future study to assess the energy requirements and potential green sources (i.e., electrical/solar) of energy to operate these diffusers should be considered.

• Development of a real-time monitoring decision support system to automatically turn on and off the air diffuser based on the in-cage temperature and DO level measurements. This could be further developed using AI (Artificial Intelligence) and ML (Machine Learning) capability to monitor and interpret ocean conditions outside the region (e.g., further to the south) and to forecast incoming conditions allowing the system to kick in to mitigate swings in temperature.

Note: The full report may be obtained from CanadianPond.ca Products Ltd.